As the main power system of industrial robots, servo motors are usually installed at the "joints" of the robot to assist in driving. The more joints there are, the more precise and intelligent the robot's motion is, and the more servo drives are needed.

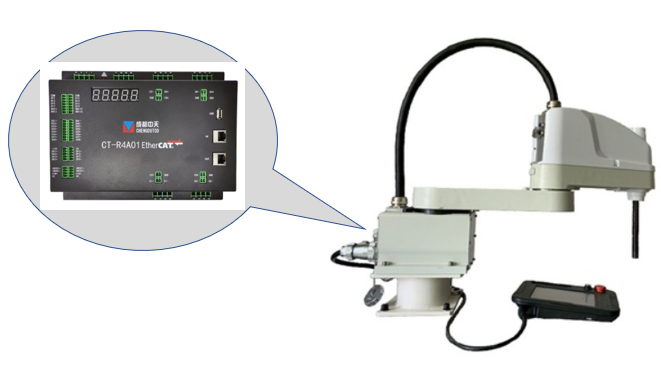

1、 4-axis robot application

Robots have a wide range of applications, including in the plastic industry, automotive industry, electronic product industry, pharmaceutical industry, and food industry. Its main feature is the ability to move objects and perform assembly work, so a series of actions such as assembly, loading and unloading, dispensing, locking screws, packaging, fixation, coating, bonding, packaging, special handling, etc. can be perfectly completed.

In 2021, robots continue to maintain rapid growth. The annual shipment exceeded 67000 units, an increase of 33%. The growth rate slowed down compared to the previous year, but still maintained a high growth rate.

The traditional driver scheme uses four separate servo drivers for separate control, with control instructions in pulse mode. The main drawback is that the integration of the electric control cabinet is not high, the body is bulky, and the overall price of the product is on the high side. The new automation adopts a high bandwidth performance FPGA+DSP solution, based on EtherCAT industrial bus communication mode, and develops a four axis integrated CT-RS4 series driver. Its four axis current loop update time is less than 1.5us, which is sufficient to ensure that the bandwidth of each axis can reach the best. Supporting the matching of third-party mature controllers, preserving customer usage habits, greatly improving the overall integration of the product, and reducing the cost of the drive by another 50%, achieving the most competitive product for customers.